Polishing metal to a mirror finish requires meticulous accuracy. It's a multi-step process involving various equipment and techniques. The journey begins with preparing the surface, removing any rust, debris, or imperfections that could obstruct the final shine. Subsequent stages involve progressively finer polishes, each designed to smooth and refine the metal's surface. With patience and practice, you can achieve a dazzling mirror finish that reflects the true beauty of your workpiece.

- Start with a thorough cleaning using a suitable solvent or abrasive cleaner.

- Step by step work your way through increasingly finer grits of sandpaper or polishing compounds.

- Apply light pressure and move the abrasive in a consistent pattern to avoid scratches.

- Finish by applying a metal polish and buffing with a soft cloth for that final mirror-like reflection.

The Art of Metal Buffing: From Rough to Radiant

Metal buffing is a craft skill that transforms rough metal into gleaming masterpieces. It's a meticulous process demanding a series of steps, each carefully click here executed to achieve the desired appearance.

A good buffing session begins with prepared metal, free from any flaws. Then, abrasive compounds are applied using a variety of tools, such as rotaries, to gradually remove imperfections and level the surface.

As the process continues, coarser compounds are replaced with finer ones, culminating in a last polish that brings out the metal's natural brilliance. The result is a piece of art that sparkles with an undeniable radiance.

Polishing Perfection: A Guide to Metal Finishing

Achieving perfect finish on metal surfaces can significantly enhance its aesthetic appeal and performance.

A wide selection of metal finishing techniques are accessible, each with its own distinct properties and applications.

From simple polishing methods to more complex processes like plating and anodizing, understanding the nuances of each technique is critical for securing the desired outcome.

Whether you're repairing an antique piece or manufacturing a new product, this guide will illuminate the world of metal finishing and provide you with the understanding to polish your metal creations.

- A multitude of factors influence the optin of a particular finishing technique, including the type of metal, its intended application, and the desired aesthetic.

- Precise preparation is crucial for achieving a high-quality finish. This involves cleaning, deburring, and frequently pre-treating the metal surface.

- Upon completion of this guide, you'll learn the fundamental principles of various finishing techniques, including grinding, electroplating, anodizing, and more.

Key Tools and Compounds for Professional Metal Polishers

Professional metal polishers rely on a range of particular tools and compounds to achieve that flawless, mirror-like finish. Their arsenal includes robust handheld buffers designed for moderate polishing action. These are paired with a variety of abrasive discs, each tailored to specific metal types and desired results. A selection of high-quality compounds, ranging from coarse cutting compounds for initial scratches removal to fine lustring liquids that impart the final shine, is also essential. Proper application techniques combined with these tools and compounds are what truly separate the amateurs from the pros.

Furthermore, professional metal polishers often utilize a range of protective equipment, such as eye protection to shield their eyes from flying debris, air filters to prevent inhalation of fine particles, and work gloves to safeguard their hands.

Unveiling Brilliance: Techniques for Polishing Precious Metals

Achieving a lustrous gleam on precious metals demands meticulous techniques and the suitable tools. A gentle technique is paramount to maintaining their inherent luster. One common method involves employing a superficial abrasive paste along with a soft cloth to erase tarnish.

- Consistent cleaning with a delicate soap and water solution can help the build-up of exterior matter.

- Special polishes formulated for different precious metals are available and offer a deeper level of luster.

- Professional jewelers possess the knowledge to revitalize severely tarnished pieces, displaying their original brilliance.

Metal Polishing 101: A Beginner's Guide to a Sparkling Finish

Ready to transform your dull metal pieces to their former glory? Polishing metal is a rewarding skill that can bring life back to anything from silverware to vintage tools. Whether you're a complete newbie or just looking to perfect your technique, this guide will walk you through the essential steps for achieving a stunning shine.

First things first, make sure to determine the type of metal you're working with. Different metals require different polishing methods and abrasives. Once you know your material, collect the necessary tools, such as a polishing cloth, rubbing compound, and perhaps a power drill for tougher jobs.

Before you begin, it's crucial to clean the metal thoroughly with soap and water to wash away any dirt or grime that could impede the polishing process.

Kelly McGillis Then & Now!

Kelly McGillis Then & Now! Barbi Benton Then & Now!

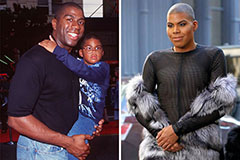

Barbi Benton Then & Now! Earvin Johnson III Then & Now!

Earvin Johnson III Then & Now! Justine Bateman Then & Now!

Justine Bateman Then & Now! Jaclyn Smith Then & Now!

Jaclyn Smith Then & Now!